Edge banding machines are essential in modern woodworking for creating smooth, durable finishes on panel edges. This article delves into the tools used in edge banding machines, highlighting their roles and specifications. Each tool serves a distinct function, ensuring a precise, seamless finish that enhances both the aesthetic and structural integrity of the workpiece.

The first woodworking tool engaged in the edge banding process is PCD pre-milling cutter. This tool is critical for ensuring a smooth surface by trimming the panel edges before applying the edge banding tape. Pre-milling removes any minor defects such as chipping or uneven surfaces, allowing for better adhesion and preventing bubbles or pinholes. The process involves two cutters rotating in opposite directions—one counterclockwise, the other clockwise—removing approximately 0.2mm of excess material.

Brazed diamond inserts: Durable and suitable for high-precision milling.

Replaceable diamond blades : Feature interchangeable diamond cutting tips for long-lasting use.

Replaceable carbide cutters: Versatile for various wood types, with replaceable cutting edges.

| Common Diamond Pre-Milling Cutter Sizes | Application Example |

|---|---|

| 125x30xH35mm Z=3+3 | KDT |

| 120x30xH43mm Z=3+3 | Nanxing |

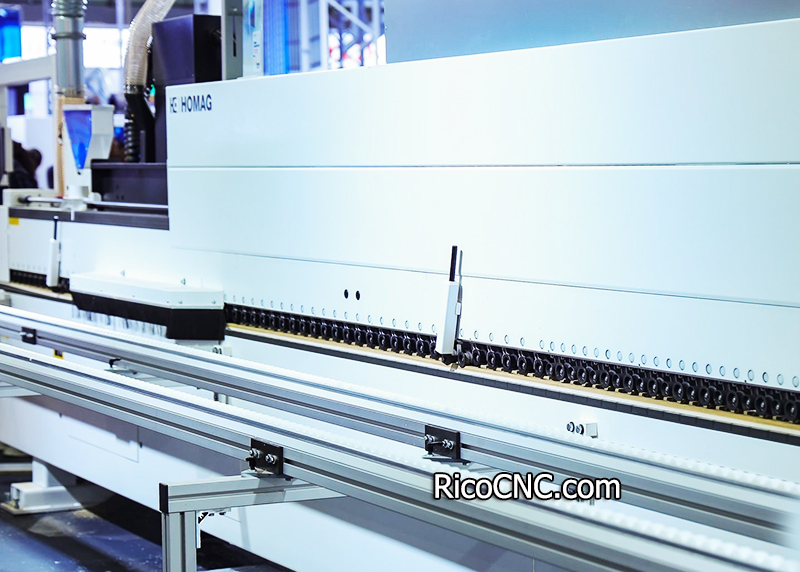

| 100x30xH48mm Z=3+3 | Homag |

| 80x30xH65mm Z3+3 | Biesse |

After applying the edge banding tape, the cut-off knife trims the excess tape. This cutting tool works pneumatically, ensuring swift and clean cuts. The most common types of cut-off knives are Homag, KDT, Nanxing styles, each offering precision and reliability for different edge banding machines.

The next stage involves trimming the excess edge banding tape from the front and rear ends of the panel using front and rear trim saw blades. These blades rotate in opposite directions, so correct installation is crucial to ensure clean, smooth cuts.

| Front and Rear Trim Saw Blade Sizes | Machine Compatibility |

|---|---|

| 104x22x3.0/2.2x30T (L/R teeth) | KDT |

| 115x22x2.6/1.8x24T (L/R teeth) | Nanxing |

| 100x22x3.5/2.5x24T L/R | Homag Brandt |

Once the edge banding tape is applied, a rough trimming cutter is used to remove the excess tape from the top and bottom edges. This trimming cutter removes about 1mm of material, ensuring the edge is prepared for fine trimming. A dull rough trimming cutter can lead to poor results, so periodic adjustments or swapping the top and bottom cutters can prolong their service life.

| Rough Trimming Cutter Sizes | Machine Compatibility |

|---|---|

| 56x16xH14*4T | KDT |

| 80x20xH19*6T | Nanxing |

| 69x16Hx18*6T | Homag |

After rough trimming, the fine trimming cutter takes over, performing the final chamfering on the edges. Chamfers are typically sized at R1.5, R2, or R3, with R1.5 and R2 being the most common for 18mm boards.

| Fine Trimming Cutter Sizes | Chamfer Size |

|---|---|

| 69x16Hx13*6T | R2 (KDT) |

| 75x20Hx16*6T | R2 (Nanxing) |

| 58x16Hx16*6T | R2 (Homag) |

The tracking cutter refines the corners of the panel, providing a polished finish after the initial edge banding process. While not always necessary, it is particularly useful for high-quality projects that demand impeccable detailing.

| Tracking Cutter Size | Application Example |

|---|---|

| 70x16Hx16*3T R2.5 | KDT |

The edge banding process often leaves small serrated or wavy marks, which can compromise the appearance of the final product. The scraper knife eliminates these imperfections, ensuring a smooth, visually appealing edge.

| Scraper Knife Size | Usage Details |

|---|---|

| 20x12x2 R2 | Double-sided; can be flipped for reuse |

The polishing cloth wheel is the final tool used in the edge banding process. It polishes the chamfered edges, ensuring a smooth and shiny finish. The wheel should be adjusted so that only 1/3 of its width touches the board's surface during the polishing process.

| Polishing Cloth Wheel Sizes | Material |

|---|---|

| 150x50x20 | Pure cloth |

| 180x50x20 | with Iron core |

What is the purpose of the pre-milling cutter in edge banding?

The pre-milling cutter trims the edges of the board to remove any unevenness or chipping, ensuring a smooth surface for the edge banding tape to adhere to. This step prevents imperfections like bubbles and pinholes in the final product.

Why are two trim saw blades used in edge banding machines?

Two trim saw blades, rotating in opposite directions, are used to trim the excess edge banding tape at the front and rear ends of the panel. This setup ensures precise and clean cuts on both ends.

How often should the rough trimming cutter be replaced or adjusted?

The rough trimming cutter should be replaced or adjusted when it becomes dull or when it no longer removes the desired amount of excess material. Regular maintenance ensures the cutter's longevity and the quality of the trimming.

What chamfer sizes are commonly used in fine trimming cutters?

The most commonly used chamfer sizes for fine trimming cutters are R1.5, R2, and R3. For 18mm boards, R1.5 and R2 are typically preferred.

How can I prolong the life of the polishing cloth wheel?

To prolong the life of the polishing cloth wheel, use only 1/3 of its width to polish the board surface and adjust its height accordingly. You can also flip the wheel to use the other side as it wears down.

This comprehensive guide to the tools used in edge banding machines highlights the precision and attention to detail required to achieve a flawless finish in woodworking. Each tool plays a critical role, from preparing the surface with pre-milling cutters to polishing the final product with a cloth wheel. Understanding their functions and maintaining them properly ensures high-quality results every time.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat