Using a CNC machine for woodworking can transform your projects, offering precision and creativity that manual methods often lack. In this article, we will explore how to effectively use a CNC router, discussing everything from the types of materials you can use to the software required, and the steps involved in your woodworking projects. Let’s dive into the world of CNC woodworking and unlock its potential!

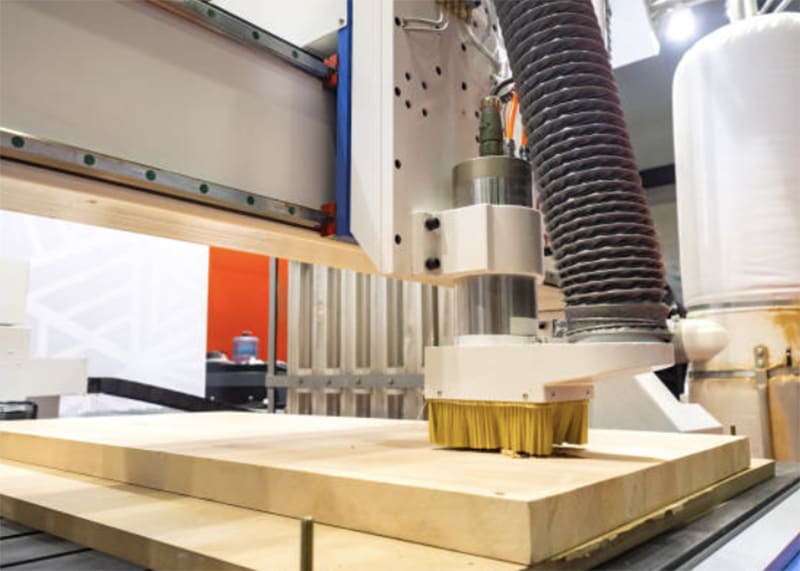

CNC stands for Computer Numerical Control, a technology that allows for the automated control of machining tools via a computer. CNC machines, especially CNC routers, are particularly popular in woodworking due to their ability to cut, carve, and engrave various materials with high precision.

A CNC router is a specific type of CNC machine designed primarily for cutting and shaping wood. Unlike traditional routers that are operated manually, CNC routers utilize G-code files to automate the cutting process. This ensures consistent results across multiple pieces, making it ideal for both small crafts and large-scale production.

CNC Router Bit: The cutting tool that determines the shape and depth of the cut.

End Mill: A type of router bit that can perform various operations, including cutting and milling.

Controller: The computer system that reads the G-code and controls the movements of the machine.

Table: The surface on which the material is placed. It can often be adjusted to accommodate various sizes of wood.

When it comes to woodworking, selecting the right material is crucial. Here are some common materials that work well with CNC routers:

| Material | Description | Pros | Cons |

|---|---|---|---|

| Plywood | Made from thin layers of wood glued together | Stable and versatile | Can splinter at edges |

| MDF | Medium-density fiberboard | Smooth surface, easy to cut | Less durable |

| Solid Wood | Natural wood cuts | Aesthetic appeal | Costly and can warp |

| Laminated Wood | Wood with a veneer finish | Cost-effective, durable | Limited customization |

| Acrylic | Plastic that mimics glass | Colorful and visually appealing | Can scratch easily |

Choosing the right material will depend on your project requirements and desired finish.

To operate a CNC router, you need appropriate software. The most commonly used types include:

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are essential for creating designs and translating them into G-code. Some popular options are:

Fusion 360: Combines CAD and CAM capabilities for detailed designs.

VCarve Pro: Ideal for creating complex shapes and engravings.

Easel: A beginner-friendly web-based application.

These software programs allow you to visualize your project, adjust dimensions, and prepare your design for the CNC machine.

Begin with a clear design. Use CAD software to sketch out your project. Ensure that dimensions are accurate and suitable for your chosen material.

Once your design is complete, export it as a G-code file. This file tells the CNC router how to move and cut the material.

Secure the Material: Place your wood on the table and secure it using clamps.

Load the G-code File: Use the CNC machine’s controller to load your G-code file.

Choose the Right Bit: Select an appropriate router bit for your project.

Before cutting your final piece, conduct a test run on a scrap piece of wood. This helps you ensure the settings are correct and can prevent costly mistakes.

Make any necessary adjustments based on the test run. This may include changing speeds, depths, or even the bit used.

Once everything is set, start the CNC machine. Monitor the process to ensure everything runs smoothly.

Regular Maintenance: Keep your CNC router in good shape by regularly cleaning and lubricating it.

Tool Selection: Choose the right router bits for your material and project type. Different bits can yield different finishes.

Speed Settings: Experiment with speed settings to find the best cut for your material.

Even seasoned woodworkers encounter challenges when using a CNC router. Here are some common problems and their solutions:

| Problem | Solution |

|---|---|

| Inconsistent cuts | Check for loose bits and recalibrate |

| Wood splintering | Adjust feed rate and bit speed |

| Software errors | Ensure you’re using compatible formats |

What is G-code?

G-code is a language used to instruct CNC machines on how to move and cut. It specifies movements, tool paths, and speeds.

How do I maintain my CNC router?

Regularly clean the machine, check for wear on bits, and lubricate moving parts to keep it functioning smoothly.

Can I use a CNC router for materials other than wood?

Yes, CNC routers can also cut materials like acrylic, plastic, and even soft metals, depending on the machine's capabilities.

Is CNC woodworking beginner-friendly?

While it can seem complex, many modern CNC routers and software are designed with beginners in mind, making it easier to start.

As technology advances, the potential for CNC woodworking continues to expand. The integration of AI and machine learning may further enhance precision and efficiency, allowing for even more intricate designs and quicker production times.

Using a CNC machine for woodworking opens up a world of possibilities, combining technology with creativity. From understanding the machine’s components to mastering the software and troubleshooting common issues, you can elevate your woodworking projects significantly. Embrace the journey and enjoy the process of creating stunning pieces that showcase your craftsmanship.

By exploring CNC technology, you position yourself at the forefront of woodworking innovation, ready to take on any project with confidence and precision.

For more insights and tips, feel free to reach out! Happy woodworking!

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat