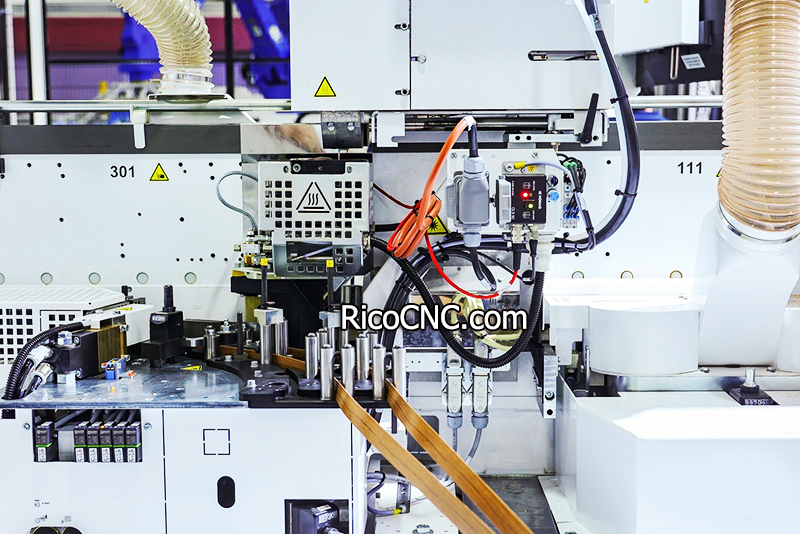

In the world of woodworking, edgebanders are essential tools for achieving clean, professional edges on cabinetry, furniture, and other wood products. However, to ensure the reliability and performance of these machines, proper maintenance is critical—particularly when it comes to the glue pot. The glue pot is at the heart of an edgebander, and effective maintenance guarantees that your machine will deliver high-quality finishes consistently. This guide will help you master edgebander glue pot maintenance, keeping your machinery in peak working condition.

The glue pot is a central component in an edgebander, designed to heat and apply adhesive to the edge of a workpiece. In particular, the glue system uses hot melt adhesives to create a strong bond between the edge tape and the panel. Without proper maintenance, the glue pot can become clogged with adhesive remnants, leading to performance issues and reduced product quality.

Maintaining the glue pot extends the lifespan of your edgebander, reduces downtime, and ensures that each panel edge is perfectly finished. Cleaning the glue system regularly can prevent many of the common problems associated with adhesive buildup, ensuring a consistently reliable machine.

The edgebander glue pot is subject to heavy use, which means regular attention is vital. Adhesive remnants left in the glue pot can quickly lead to operational problems. These remnants accumulate over time, affecting the quality of adhesion and the smoothness of the finish.

Consistent cleaning of the glue pot not only extends the equipment's life but also ensures that your glue system remains efficient, minimizing downtime. Poor maintenance can lead to glue degradation, causing unwanted stickiness, uneven application, or glue discoloration, all of which impact the end product negatively.

Benefits of Regular Glue Pot Maintenance:

Improved product quality

Reduced adhesive waste

Prolonged machine lifespan

Decreased production downtime

To understand maintenance properly, it helps to know the key components of a glue pot system. These include the heating elements, the glue pot reservoir, application rollers, and temperature sensors. All these components must work seamlessly together to provide effective adhesion and smooth edgebanding.

Glue Pot Reservoir: The part that stores and heats the adhesive. Keeping it clean is vital for preventing buildup.

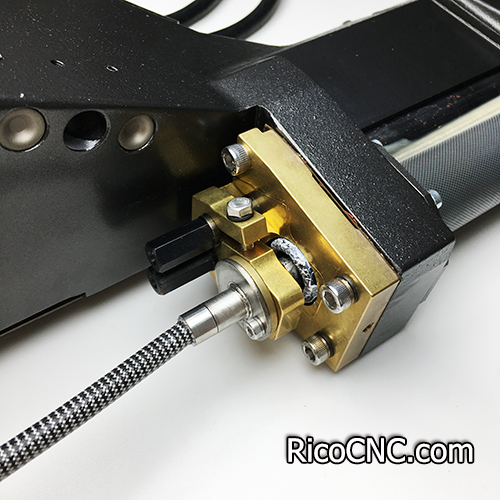

Glue Rollers: These rollers apply the heated glue to the material. Adhesive remnants on these rollers can lead to uneven glue spread and reduced product quality.

Heating Elements: These are responsible for melting the adhesive. If adhesive builds up on the heating elements, it can cause temperature inconsistencies.

Temperature Sensors: Ensuring these sensors remain clean is crucial for accurate temperature control, which in turn affects the glue consistency.

Glue Level Sensor: The glue level sensor helps monitor the amount of adhesive in the glue pot, ensuring the edgebander has sufficient glue during operation and reducing interruptions due to low adhesive levels.

A successful maintenance routine starts with efficient cleaning techniques. Cleaning the glue pot is essential for keeping adhesive remnants from accumulating, which can affect the glue system’s efficiency.

Switch Off the Machine and Cool Down: Safety comes first—always turn off the edgebander and allow the glue pot to cool before attempting to clean it.

Remove Adhesive Remnants: Use a scraper or a cleaning solution specifically designed for glue pots to remove the glue remnants. Mechanical scrapers work well to dislodge hardened glue without damaging the pot.

Use a Cleaning Agent: Once the bulk of the adhesive has been removed, a special glue pot cleaner can be applied. This solution softens any stubborn glue remnants and makes the final wipe-down easier.

Wipe Down the Pot: Use a clean, dry cloth to remove any residue, ensuring that no remnants are left behind.

Check the Rollers: Adhesive remnants can also accumulate on application rollers, leading to uneven glue application. Use a suitable cleaner to wipe down these rollers thoroughly.

Tips for Effective Cleaning:

Clean the glue pot regularly, ideally at the end of each workday, to prevent the glue from hardening.

Avoid using metal tools that could damage the glue pot surface.

Use personal protective equipment (PPE) when dealing with cleaning agents.

Neglecting glue pot maintenance leads to a range of issues that can compromise not only the edgebander's efficiency but also the quality of the finished product.

Glue Contamination: When adhesive remnants build up, they can degrade and mix with fresh glue, leading to reduced adhesion strength and a poor finish.

Temperature Inconsistencies: Build-up on heating elements or temperature sensors can lead to inconsistent heating, affecting the glue's melting point and thus the quality of the adhesion.

Machine Downtime: Clogged glue pots require more significant interventions, which can lead to unexpected downtime and disrupt production schedules.

To avoid these issues, a proactive approach to glue pot maintenance is key. Not only does it prevent major problems, but it also maintains the quality of each product coming out of your woodworking shop.

The performance of your glue system doesn’t just depend on cleaning—choosing the right adhesive is crucial. Various adhesives are used in edgebanders, and each has unique properties that affect how it interacts with the glue pot and other parts of the edgebander.

EVA (Ethylene Vinyl Acetate): The most commonly used adhesive for edgebanders. It offers good bonding strength and is relatively easy to clean.

PUR (Polyurethane): Known for its superior bonding properties and resistance to moisture and heat. However, it requires careful maintenance because it tends to harden permanently.

Each adhesive has its pros and cons, but what remains consistent is the need to maintain a clean glue system to prevent remnants from causing bonding issues.

Material Type: Different adhesives work better on different materials—whether you are using melamine, ABS, or PVC edge banding.

Glue Pot Compatibility: Not all glue pots are designed to handle all adhesive types. Ensure compatibility to prevent damage to your edgebander.

Cleaning Frequency: Some adhesives, like PUR, demand more frequent cleaning. Always factor this into your maintenance schedule.

To keep your edgebander functioning at its best, establishing a consistent maintenance schedule is essential. A structured routine ensures that no part of the glue system is overlooked, which in turn guarantees that the machine delivers optimum performance.

Clean the Glue Pot: Wipe down the glue pot after every use, ensuring that no adhesive is allowed to harden.

Inspect for Residue: Check the rollers and the glue pot for any leftover adhesive remnants.

Temperature Control: Make sure the glue pot is cooling down as expected. Rapid temperature changes can affect glue quality.

Deep Cleaning: Use a more thorough cleaning method, including applying glue pot cleaner.

Inspect Rollers and Sensors: Make sure all moving parts are free of glue and functioning smoothly.

Inspect Heating Elements: Adhesive remnants may build up near the heating elements. Ensure they are free of any residue.

Check Glue Pot Bearings: These can be affected by glue spills or buildup, and ensuring their cleanliness ensures smooth machine function.

How often should I clean the edgebander glue pot?

It is recommended to clean the glue pot at the end of each workday. This helps prevent glue remnants from hardening and causing issues with future use.

What type of cleaner should I use for adhesive remnants?

A specialized glue pot cleaning solution is ideal. These cleaners are designed to soften adhesive remnants without damaging the pot.

Can I use metal tools to scrape off the glue?

No, using metal tools can scratch the surface of the glue pot, leading to further complications. Instead, use plastic scrapers that are designed for glue removal.

What happens if I don’t clean my glue pot regularly?

Neglecting glue pot maintenance can lead to glue contamination, temperature inconsistencies, and ultimately, machine downtime. It may also lead to poor adhesion and compromised product quality.

Edgebander glue pot maintenance is essential for any woodworking professional aiming to achieve high-quality, consistent results. Keeping the glue system clean prevents adhesive remnants from causing problems, maintains the machine's efficiency, and ensures the longevity of the edgebander.

Establishing a regular maintenance schedule, using the right cleaning agents, and selecting the appropriate adhesives will help you get the best performance from your edgebander. By investing time in proper glue pot maintenance, you ultimately save money, reduce downtime, and keep your customers satisfied with a consistent, quality product.

Maintaining the glue pot might seem like a small part of the overall process, but it's crucial in ensuring that your edgebanding tasks are smooth, reliable, and professional-looking every time.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat