Edgebanding machines are crucial in woodworking, especially for ensuring smooth and finished edges on panel-based products. When maintained correctly, these machines not only increase efficiency but also deliver exceptional results every time. In this comprehensive guide, we explore the essentials of edgebanding machine maintenance to help you extend your machine's lifespan and ensure continuous productivity.

Maintaining an edgebanding machine is more than just keeping it running. Regular maintenance helps avoid unexpected downtimes, keeps the quality of the finished product consistently high, and ensures that your investment lasts for years.

Maintaining your edge banding machine offers numerous benefits. Below, we delve into some of the most significant ones:

Reduced Downtime: Downtime can cost businesses time and money. With proper maintenance, unexpected breakdowns are minimized.

Longer Machine Lifespan: Routine care extends the overall life of the edge banding machine, saving you from costly replacements.

Better Edge Quality: A well-maintained machine will always provide clean, precise edges.

Consistent Performance: Optimal machine functioning ensures your project quality is consistent, helping build a reputation for quality products.

"Prevention is better than cure, and this holds especially true for machines. A well-maintained edge banding machine will always outperform one that is neglected."

Like any other machine, edge banding machines require regular attention. A daily maintenance routine ensures smooth operations and helps identify any issues early before they escalate. Here is what you should do daily:

Dust and debris accumulate daily, especially when dealing with wood. Keeping your machine clean is the most crucial aspect of maintaining it. Follow these steps to clean your edge banding machine:

Remove Sawdust: Use a blower to clear the sawdust accumulated around critical components like the trimmer, glue pot, and pressure rollers.

Wipe Glue Residues: Glue residues around the glue pot and edge banding area can harden over time, impacting machine efficiency. Wipe down these areas with a damp cloth daily.

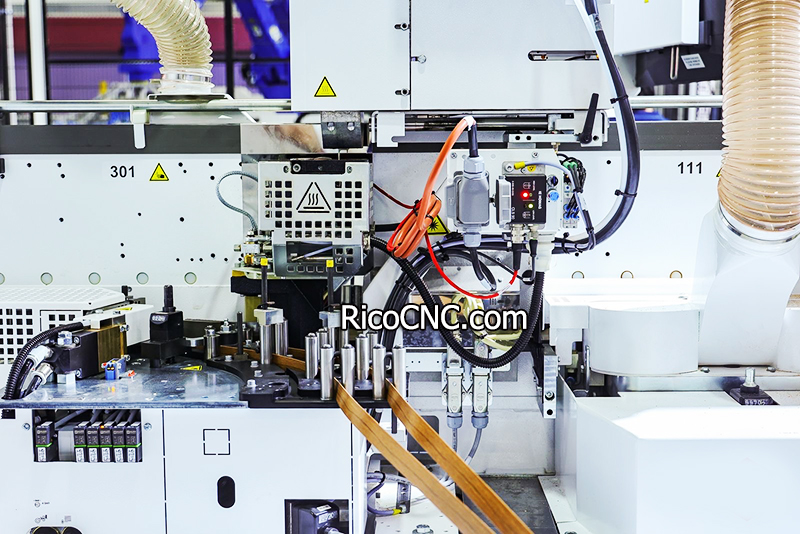

An edgebanding machine has several moving parts such as feed rollers, glue applicator, trimmers, and heating components. Daily inspection ensures early identification of wear or mechanical issues.

Lubricate Components: Ensure that the bearings and rollers are adequately lubricated. Proper lubrication prevents unnecessary wear and tear.

Check Trimming Blades: Ensure trimming blades are sharp and free of obstructions. Dull blades affect the quality of the banding and can cause mechanical stress on the machine.

Each day, before you begin production, it's advisable to test the operational settings. Make sure to test:

Temperature Settings: Verify that the glue pot temperature is at optimal levels.

Pressure Rollers: Test the pressure applied by rollers to ensure it’s uniform and sufficient to hold the edge material correctly.

Apart from daily maintenance, a more detailed check-up should be conducted weekly. Weekly maintenance focuses on ensuring all components are running smoothly and involve adjustments and replacements if required.

Glue pots are critical to the operation of edgebanding machines. Here’s how to maintain them weekly:

Clean Out Old Glue: If the machine is idle for extended periods, glue left in the glue pot can become ineffective and may affect the quality of adhesion. Clean out the glue pot at least once a week to prevent residue build-up.

Check Glue Flow: Ensure the glue application is consistent without any clogging. Clogging can reduce the quality of the banding.

Edge banding machines contain multiple sensors, control panels, and heating systems. A weekly inspection can help prevent faults:

Inspect Wiring: Look for frayed or loose wiring. This simple step can prevent short circuits and improve safety.

Control Calibration: Ensure the control panel is working as intended and all the sensors are calibrated correctly.

Blunt blades can reduce the quality of the final product and cause excessive wear on the machine. Inspect and sharpen cutter and trimmer blades weekly for consistent cutting quality.

Monthly maintenance focuses on a deeper inspection of the machine's components, looking for signs of long-term wear, replacing parts if necessary, and ensuring that machine calibration is accurate.

The feed system is critical to ensuring the edge banding is applied uniformly along the length of the panel.

Check the Feed Chain: Inspect the feed chain for wear and ensure it’s properly lubricated.

Check Feed Speed Settings: Adjust and calibrate feed speed as required for different panel materials to avoid any inconsistencies.

Bearings and bushings facilitate the smooth movement of various components within the edge banding machine.

Lubricate Bearings: Lubricate all bearings and moving joints. Make sure to use the manufacturer-recommended lubricant for optimal performance.

Inspect Bushings for Wear: If there are any signs of wear, replace them immediately to prevent any chain reactions that could cause severe machine damage.

Being aware of common issues can help you avoid them and maintain an efficient workflow. Below are some common problems that may arise with edgebanding machines and how to prevent them:

One of the most frequent issues in edgebanding is poor glue application, leading to poorly attached banding.

Issue: Glue not adhering well to the material.

Solution: Regularly clean the glue pot and ensure that the temperature is set correctly. It’s also important to use quality glue suitable for your edge banding material.

Uneven banding leads to poor aesthetics and possible damage to the panel.

Issue: The edge banding material is applied unevenly.

Solution: Regularly adjust the pressure rollers and feed speed to make sure the banding material stays in place consistently during application.

Blunt cutters or trimmers result in chipped or rough edges, lowering the final product’s quality.

Issue: Dull trimming blades causing chipped edges.

Solution: Regularly inspect and sharpen or replace trimmer blades. Keeping the blades sharp ensures clean and smooth edges.

Machine maintenance involves handling moving parts, electrical components, and sometimes high temperatures. Safety must always be a priority during maintenance activities.

Turn Off Power: Always turn off the power supply before starting any maintenance work. This avoids accidental injuries.

Use Proper Insulated Tools: Always use tools with insulated handles when working on electrical components to prevent electric shocks.

Wear Gloves: The edges of panels and blades are sharp, and gloves will help you avoid injuries.

Eye Protection: Eye protection is necessary when cleaning components or blowing out sawdust to prevent any dust or debris from entering your eyes.

Glue can be dangerous if it comes into contact with your skin or eyes. Ensure to:

Work in a Well-Ventilated Area: Glue fumes can be harmful if inhaled excessively.

Avoid Contact with Skin: Always wear gloves when handling glue.

The proper tools make maintenance easier and more efficient. Below is a list of tools that are essential for edgebanding machine maintenance:

| Tool | Purpose |

|---|---|

| Lubricating Oil | Lubricates moving parts |

| Multimeter | Checks electrical connections |

| Sharpening Stone | Sharpens cutter and trimmer blades |

| Cleaning Brush | Removes dust and residue |

| Insulated Screwdrivers | For electrical component maintenance |

Choosing the correct glue is critical to achieving high-quality edgebanding. Not all glues are created equal, and the right glue depends on the type of material, temperature, and application method.

EVA (Ethylene Vinyl Acetate): One of the most common types of glue used in edgebanding. EVA glue is cost-effective and easy to work with. However, it may not offer as much heat and moisture resistance as other options.

PUR (Polyurethane): PUR glue is excellent for applications requiring high moisture and heat resistance. It forms a very strong bond but is more challenging to work with compared to EVA.

Keeping your edge banding machine in prime condition helps extend its life beyond the expected period. Below are some tips to achieve that:

Use high-quality glue, banding materials, and lubrication oils. While cheaper alternatives may seem like a good deal initially, they often cause more wear and tear, leading to increased maintenance costs in the long term.

Ensure the operators and maintenance staff are well-trained. Proper use and care by the personnel handling the machine are vital for maximizing its lifespan.

Get your edgebanding machine professionally serviced annually. A professional can spot potential issues that are easy to miss and carry out more complex maintenance activities.

Remember, the key to a long-lasting machine is consistent, preventive maintenance rather than reactive repairs. A well-maintained edgebanding machine will serve you well, providing smooth, perfect edges that your customers will appreciate for years to come.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat