Cleaning an edgebander glue pot is a critical maintenance task that helps maintain the performance and longevity of your edgebander. Whether you’re a woodworking enthusiast or a professional working with an industrial edge banding machine, regular cleaning is essential to ensure a smooth production line and to avoid costly repairs. In this article, we will discuss why cleaning is important, the materials needed, and a detailed step-by-step guide on how to clean an edgebander glue pot effectively.

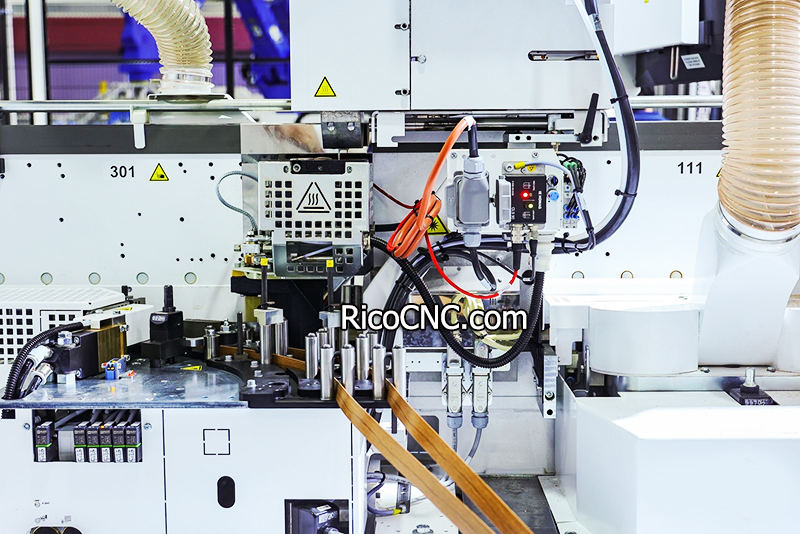

The edgebander glue pot contains several key parts, such as the glue roller, heating cartridge, glue level sensor, glue unit bushing, and seal gasket. These components work together to ensure that glue is properly heated, circulated, and applied to the edge banding material.

The glue pot in an edgebander plays a crucial role in bonding the edge banding material to the wood. It continuously heats and circulates adhesive, ensuring that the glue is applied evenly to the wood edge. Over time, adhesive remnants can build up inside the glue pot, leading to several issues:

Reduced Efficiency: Old glue residues can block the smooth flow of adhesive, affecting the glue system's efficiency.

Poor Bond Quality: Built-up adhesive remnants can compromise the quality of the bond, leading to weaker, inconsistent edge banding.

Increased Maintenance Costs: Neglecting regular cleaning can lead to machine malfunctions, requiring costly repairs or even replacement of components.

Regular cleaning keeps the glue pot functioning optimally, reduces downtime, and maintains the high-quality finishes required in the woodworking industry.

Cleaning the glue pot is a relatively straightforward process if you have the right tools. Here is a list of tools and materials that you will need:

Scraper Tool: For removing hardened glue from the pot walls.

Heat Gun: Helps soften hardened glue, making it easier to scrape.

Cleaning Solvent: Special glue pot cleaning agents to dissolve glue remnants.

Protective Gloves: Glue and solvents can be harsh on the skin.

Brass Brush: To scrub off any leftover adhesive.

Cloth/Rags: For wiping down surfaces.

Safety Goggles: To protect your eyes from glue particles and solvents.

Cleaning an edgebander glue pot may seem like a daunting task, but following these steps will make the process simple and efficient. Below is a detailed guide on how to get the job done effectively.

The first step is to turn off the edgebander and allow it to cool down.

Turn Off Safely: Always ensure that the machine is completely powered down and unplugged before beginning any maintenance work.

Allow the Glue Pot to Cool: Let the glue pot cool down to a safe temperature, but not completely cold, as glue is easier to clean when it’s slightly warm.

Safety Tip: Never attempt to clean the glue pot while the machine is fully operational or extremely hot, as it poses a significant safety risk.

Once the glue pot has cooled to a manageable temperature, it's time to soften the hardened glue.

Use a Heat Gun: Apply heat evenly around the glue pot using a heat gun. This will help soften the glue, making it easier to remove.

Avoid Overheating: Be careful not to overheat the pot, as excessive heat can damage the glue system or other sensitive parts.

The goal is to soften the glue enough to make it pliable for scraping, without causing damage to the glue pot or surrounding components.

With the glue softened, use a scraper tool to remove the majority of the adhesive remnants.

Scrape Gently: Scrape along the edges and bottom of the glue pot, removing as much glue as possible. Be thorough but avoid using excessive force that might damage the glue pot.

Work in Sections: If the glue pot is large, work in sections to ensure that each area is cleaned thoroughly.

After scraping off the bulk of the glue, apply a cleaning solvent to dissolve any remaining glue.

Use a Brass Brush: Apply the cleaning solvent to the inside of the glue pot, then use a brass brush to scrub off any remaining adhesive.

Let the Solvent Sit: Allow the cleaning solvent to sit for a few minutes to dissolve any stubborn glue remnants.

Cleaning solvents are specifically designed to break down adhesives, making this an essential part of the process for achieving a fully cleaned glue pot.

Once the glue and solvent have been removed, wipe down the glue pot with a clean cloth or rags.

Wipe Thoroughly: Make sure all glue residues are wiped away, leaving a clean surface.

Inspect for Residue: Inspect the glue pot carefully for any leftover glue. Repeat the process if necessary.

A well-cleaned glue pot should have no visible remnants or build-up, ensuring the glue system is ready for the next use.

After ensuring that the glue pot is clean, reassemble any parts that were removed and test the machine.

Reassemble Carefully: Make sure all components are securely reattached.

Test the Glue Flow: Run a quick test to make sure the glue system is functioning properly and that glue is flowing smoothly.

Regular testing after cleaning helps ensure that the edgebander is ready for use without any operational hiccups.

Cleaning an edgebander glue pot can be a challenging task, but with these useful tips, you can make the process more manageable:

Clean Regularly: Set a maintenance schedule to clean the glue pot regularly to avoid excessive build-up. Frequent cleaning means less effort each time.

Use High-Quality Solvents: Not all solvents are created equal. Always use high-quality cleaning solvents designed for edgebander glue pots to achieve the best results.

Use Proper Safety Equipment: Always wear protective gloves and safety goggles to protect yourself from hot glue and harsh cleaning chemicals.

Avoid Overheating: When softening the glue with a heat gun, always monitor the temperature to prevent damage to the glue pot.

When cleaning an edgebander glue pot, there are some common mistakes that many people make. Avoiding these mistakes will make the cleaning process smoother and safer:

Waiting Too Long Between Cleanings: Allowing glue to build up excessively will make it much harder to clean and can damage the glue pot.

Using the Wrong Tools: Using abrasive tools can scratch or damage the glue pot. Stick to the recommended tools such as scrapers and brass brushes.

Not Heating the Glue Properly: If the glue is not softened adequately before scraping, it can lead to frustration and potential damage to the pot.

By avoiding these mistakes, you can ensure a smoother cleaning process and extend the lifespan of your edgebander machine.

Maintaining a clean glue pot is vital to the overall functionality and efficiency of your edgebander machine. Here are some key benefits:

A clean glue pot ensures that the glue is distributed evenly along the wood edge. This leads to better adhesion quality and results in a stronger, more durable bond for your edge banding.

Cleaning the glue pot regularly helps prevent machine malfunctions, thus reducing downtime. This means you can maintain a continuous production line without unexpected interruptions.

Adhesive build-up can eventually lead to component failure, which may require costly replacements. Regular cleaning helps to avoid this, thereby extending the lifespan of the edgebander machine.

A clean glue pot contributes to a more consistent quality of edge banding. When the glue flow is smooth and there are no blockages, the final product maintains a professional finish.

How often should I clean the edgebander glue pot?

It is recommended to clean the glue pot every 8 to 12 hours of continuous operation. However, the frequency may vary depending on the type of adhesive used and the production volume.

Can I use any solvent to clean the glue pot?

No, you should use a solvent specifically designed for cleaning edgebander glue pots. These solvents are formulated to dissolve the glue without damaging the machine components.

Is it necessary to heat the glue pot before cleaning?

Yes, heating the glue helps soften it, making it easier to scrape and remove. A heat gun can be used for this purpose, but avoid overheating to prevent damage.

What safety precautions should I take when cleaning the glue pot?

Always wear protective gloves and safety goggles to protect your hands and eyes from hot glue and harsh chemicals.

Can I clean the glue pot while the machine is hot?

No, it is not safe to clean the glue pot while the machine is extremely hot. Allow it to cool down to a safe temperature to avoid burns and accidents.

What happens if I don't clean the glue pot regularly?

Failure to clean the glue pot regularly can lead to adhesive build-up, which may affect the glue system's efficiency, compromise bond quality, and lead to potential machine breakdowns.

Cleaning an edgebander glue pot is a vital maintenance task that should never be overlooked in the woodworking industry. By following a regular cleaning schedule and using the correct tools and methods, you can ensure your edge banding machine operates at its best, providing high-quality, durable finishes. Proper maintenance not only improves the machine's efficiency but also extends its lifespan, saving you time and money in the long run.

If you’re looking for more insights on maintaining your woodworking tools or need advice on purchasing the best cleaning supplies or want to purchase purchase edgebander glue pot or parts for your glue system, contact us today. We're here to help keep your woodworking processes running smoothly and efficiently.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat