Edge banding is a crucial finishing touch in woodworking, but the real magic happens when you trim it perfectly. This comprehensive guide will walk you through the process of trimming edge banding, ensuring your plywood projects look sleek and professional. Whether you're a DIY enthusiast or a seasoned woodworker, these techniques will elevate your craftsmanship to new heights.

Edge banding is a thin strip of material, typically wood veneer or PVC, applied to the exposed edges of plywood or particleboard. But why does it need trimming?

1. Excess Material: Edge banding is often applied with a slight overhang to ensure full coverage.

2. Flush Finish: Trimming creates a smooth, flush surface between the edge and the panel.

3. Professional Look: Properly trimmed edges give your project a polished, high-quality appearance.

Understanding the importance of trimming is the first step towards achieving that perfect finish on your woodworking projects.

Before diving into the trimming process, let's gather the essential tools:

Sharp utility knife

Sandpaper (various grits)

File or wood rasp

Safety glasses and dust mask

For more precise and efficient trimming, especially on larger projects, consider using a CNC router. These machines offer unparalleled accuracy and can save you significant time on complex projects.

Proper preparation is key to achieving a clean trim:

1. Allow the edge banding to cool completely if you've just applied it with heat.

2. Ensure your work area is well-lit and clean.

3. Secure your workpiece to prevent movement during trimming.

4. Put on your safety gear, including glasses and a dust mask.

Taking these preparatory steps will set you up for success and help prevent accidents or mistakes during the trimming process.

There are several methods for trimming edge banding, each with its own advantages:

1. Manual Trimming with a Utility Knife:

Ideal for small projects or tight spaces

Requires a steady hand and patience

Best for thin veneer edge banding

2. Using an Edge Trimmer:

Faster and more consistent than manual trimming

Great for straight edges

Available in manual and electric versions

3. Router with a Flush Trim Bit:

Provides the most professional finish

Ideal for large projects or thick edge banding

Requires more setup but offers superior results

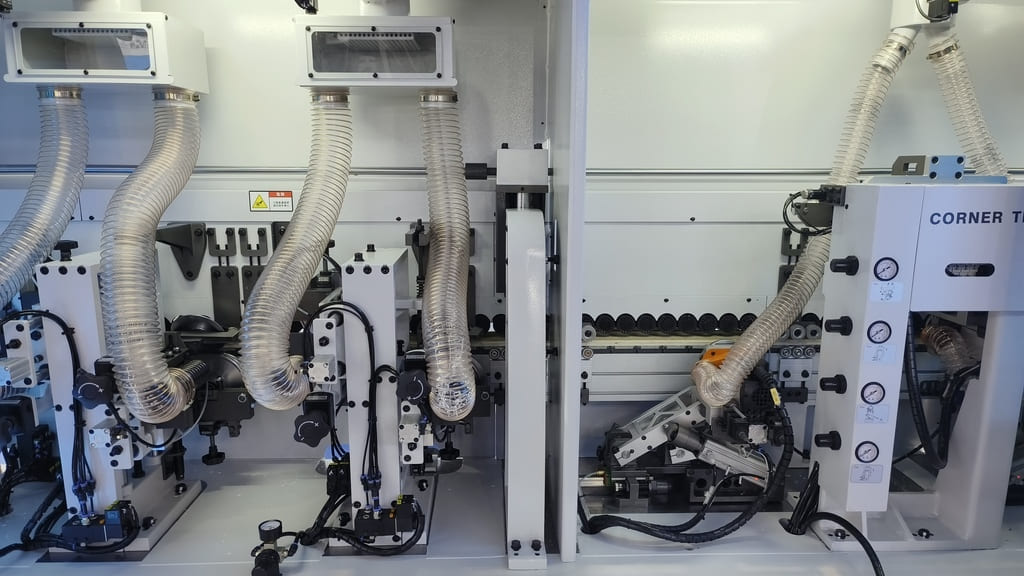

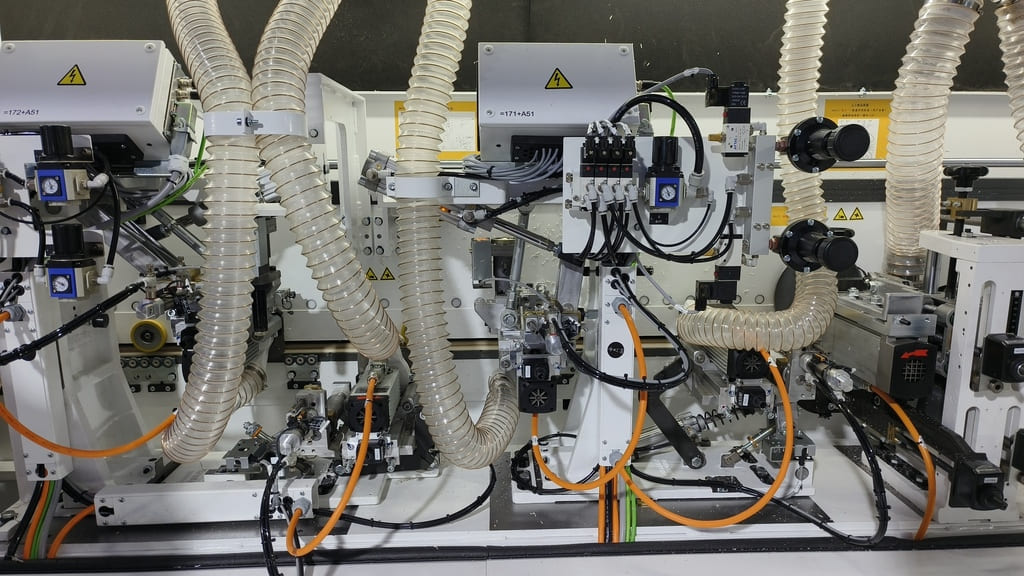

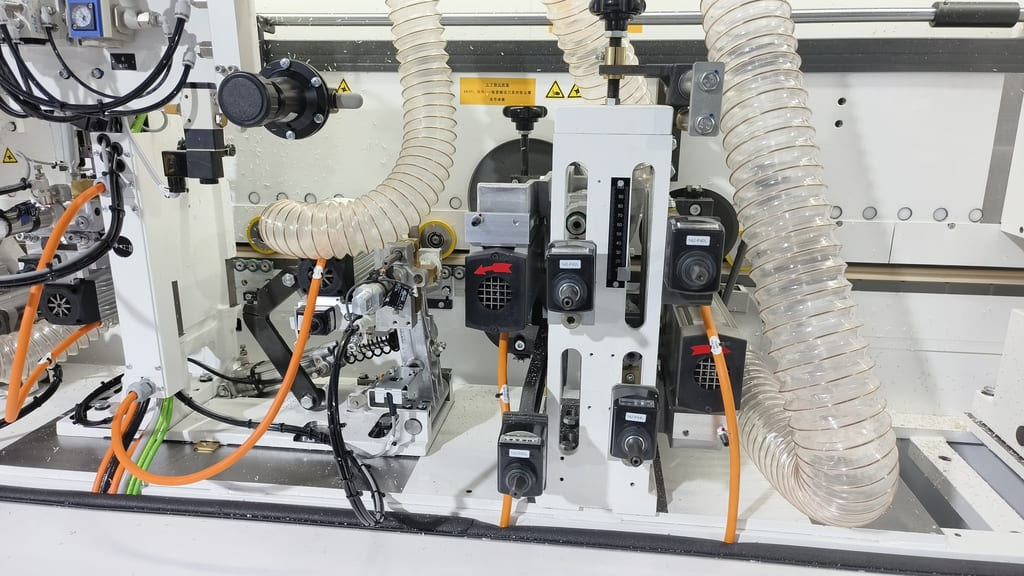

For the best results on larger projects, consider using an edge bander with a built-in trimming function. This can significantly streamline your workflow and ensure consistent results.

For those working on smaller projects or with limited tools, here's how to trim edge banding using a utility knife:

1. Start at one end of the edge, holding the knife at a slight angle.

2. Apply steady pressure and draw the knife along the edge, trimming off the excess.

3. Make multiple light passes rather than trying to remove all excess in one go.

4. Be extra careful around corners to avoid chipping or tearing.

Remember, patience is key when using this method. Take your time to achieve a clean, even trim.

Edge trimmers are specialized tools designed specifically for this task. Here's how to use one:

1. Adjust the trimmer blade to match the thickness of your edge banding.

2. Place the trimmer against the edge, ensuring it's flush with the surface.

3. Apply gentle pressure and move the trimmer along the edge in a smooth, continuous motion.

4. Make a second pass if necessary to catch any missed spots.

Edge trimmers can significantly speed up the process, especially on straight edges. They're a worthwhile investment for anyone who frequently works with edge banding.

Using a router with a flush trim bit is often considered the preferred method for achieving a perfect trim:

1. Install a flush trim bit in your router.

2. Set the bit depth so that it just barely touches the surface of your workpiece.

3. Start the router and carefully guide it along the edge, keeping the bearing flush against the surface.

4. Move the router in a smooth, consistent motion for the best results.

For added stability and precision, consider using a router table. This setup can provide even more control, especially when working with larger pieces.

Curved edges present a unique challenge when trimming edge banding. Here are some tips:

1. Use a flexible edge trimmer designed for curves.

2. Take your time and make multiple light passes.

3. For tight curves, a sharp utility knife may be more effective than mechanical trimmers.

4. Sand carefully after trimming to ensure a smooth transition.

Remember, patience is crucial when working with curved edges. Don't rush the process, as this can lead to mistakes or damage to your workpiece.

After trimming, a few finishing steps will ensure a professional look:

Sand the trimmed edge lightly with fine-grit sandpaper.

Use a file or wood rasp to smooth any rough spots.

Clean the edge with a tack cloth to remove dust.

Apply a finish that matches your project, if desired.

These final touches will help blend the edge banding seamlessly with your workpiece, creating a polished, professional appearance.

Even experienced woodworkers can make mistakes. Here are some common pitfalls to watch out for:

Rushing the process, which can lead to uneven trimming or damage.

Using dull tools, which can tear the edge banding.

Applying too much pressure, potentially causing the edge banding to chip or peel.

Neglecting to sand after trimming, leaving a rough or uneven edge.

Forgetting to account for wood movement, which can cause edge banding to separate over time.

By being aware of these potential issues, you can take steps to avoid them and ensure a successful edge banding application.

Sometimes, despite your best efforts, issues can arise. Here's how to troubleshoot common problems:

Chipping: Try reducing your trimming speed or using a sharper blade.

Uneven Trim: Double-check your tool settings and ensure you're maintaining consistent pressure.

Peeling: This could indicate poor adhesion. Reapply the edge banding, ensuring proper heat and pressure.

Visible Glue Lines: Clean up with a solvent designed for your adhesive type, then sand lightly.

Remember, practice makes perfect. Don't be discouraged if your first attempts aren't flawless – with time and experience, you'll achieve professional-looking results.In conclusion, mastering the art of trimming edge banding is a valuable skill that can significantly enhance the quality of your woodworking projects. By following these guidelines and practicing your technique, you'll be able to achieve clean, professional-looking edges that will make your work stand out.Key takeaways:

Choose the right trimming method for your project and skill level

Prepare your workpiece and tools properly before starting

Take your time and maintain consistent pressure when trimming

Pay extra attention to curved edges and corners

Always finish with light sanding for a smooth, seamless look

Be aware of common mistakes and how to troubleshoot issues

Remember, like any woodworking skill, trimming edge banding takes practice. Keep at it, and soon you'll be creating beautifully finished pieces with ease.

If you need any woodworking machinery parts, please contact us

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat