Edge banding machines have revolutionized the furniture industry, transforming the way we create beautiful, durable wood furniture and cabinets. These innovative devices apply edge banding material to the exposed edges of engineered wood panels, creating a seamless, professional finish that enhances both aesthetics and durability. In this comprehensive guide, we'll explore the significance of edge banding machines in furniture manufacturing, their various types, and how they've become an indispensable tool for craftsmen and large-scale producers alike.

An edge banding machine is a specialized piece of equipment designed to apply thin strips of material (edge banding) to the exposed edges of engineered wood panels, such as particleboard or MDF. This process creates a smooth, finished appearance and protects the edges from damage and moisture.Edge banding machines come in various sizes and configurations, from small, portable units suitable for DIY enthusiasts to large, industrial-grade machines used in high-volume furniture manufacturing. These machines typically use heat and adhesive to bond the edge banding material to the panel, creating a seamless and durable finish.Learn more about the basics of edge banding

Edge banding machines play a crucial role in modern furniture production for several reasons:

1.Aesthetics: They create a polished, professional look by concealing the raw edges of engineered wood panels.

2.Durability: Edge banding protects the vulnerable edges of panels from damage, moisture, and wear.

3.Efficiency: Automated edge banding is much faster and more consistent than manual methods.

4.Versatility: Machines can apply various types of edge banding materials to suit different design needs.

5.Cost-effectiveness: By streamlining the production process, edge banding machines help reduce labor costs and material waste.

For furniture manufacturers, investing in quality edge banding equipment is not just a luxury – it's a necessity for staying competitive in today's market.

Edge banding machines come in several varieties, each suited to different production needs and scales:

1.Manual Edge Banders: Ideal for small workshops or DIY projects, these portable machines require the operator to guide the panel through manually.

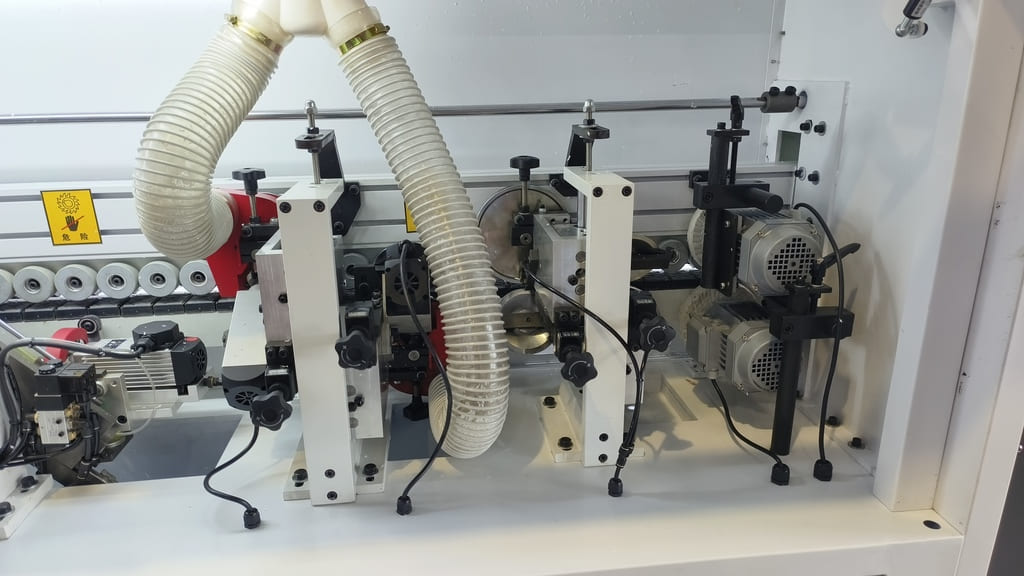

2.Semi-Automatic Edge Banding Machines: These offer a balance between affordability and efficiency, with some automated features but still requiring operator involvement.

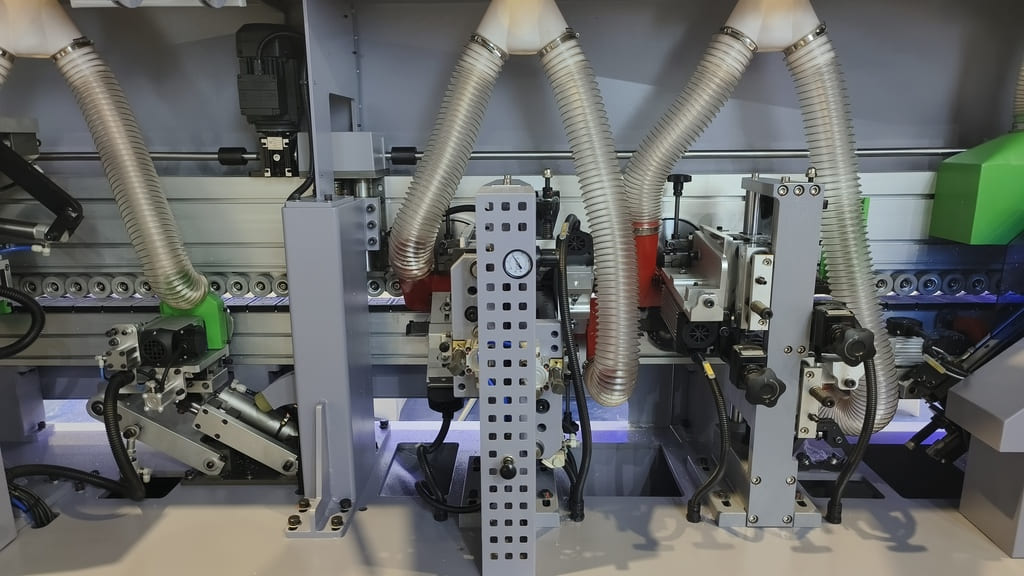

3.Fully Automatic Edge Banding Machines: High-capacity machines that can handle large volumes of panels with minimal human intervention.

4.CNC Edge Banding Machines: Integrated into CNC (Computer Numerical Control) systems for precise, programmable edge banding as part of a larger automated production line.

5.PUR Edge Banding Machines: Specialized machines that use Polyurethane Reactive (PUR) adhesive for superior bonding strength and moisture resistance.

The choice of machine depends on factors such as production volume, available space, budget, and specific edge banding requirements.Discover the best edge banding machine for your needs.

Edge banding machines significantly enhance the quality of furniture in several ways:

1.Consistency: Automated application ensures uniform edge banding thickness and alignment.

2.Precision: Advanced machines can achieve extremely tight tolerances, resulting in nearly invisible seams.

3.Durability: Properly applied edge banding protects panel edges from chipping, peeling, and moisture damage.

4.Variety: Machines can apply a wide range of edge banding materials, including PVC, wood veneer, and ABS, allowing for diverse design options.

By delivering these quality improvements, edge banding machines help furniture manufacturers meet and exceed customer expectations.

Edge banding machines are versatile and can work with various materials, including:

-PVC (Polyvinyl Chloride): Durable and cost-effective, available in many colors and patterns.

-ABS (Acrylonitrile Butadiene Styrene): Offers excellent impact resistance and color stability.

-Wood Veneer: Provides a natural wood appearance for high-end furniture.

-Melamine: An economical option that's easy to clean and maintain.

-Acrylic: Offers a high-gloss finish for modern furniture designs.

The choice of material depends on the furniture's intended use, aesthetic requirements, and budget considerations.

Edge banding machines significantly boost production efficiency through:

1.Speed: Automated machines can process panels much faster than manual methods.

2.Reduced Labor: Less human intervention means lower labor costs and fewer errors.

3.Minimized Waste: Precise application reduces material waste and rework.

4.Consistency: Uniform results mean fewer quality control issues and rejections.

By streamlining the edge banding process, these machines allow furniture manufacturers to increase output while maintaining high quality standards.Explore ways to optimize your edge banding process

Selecting the right edge banding machine is crucial for your furniture manufacturing operation. Consider these factors:

1.Production Volume: Match the machine's capacity to your production needs.

2.Panel Sizes: Ensure the machine can accommodate your typical panel dimensions.

3.Edge Banding Materials: Choose a machine compatible with your preferred edge banding types.

4.Automation Level: Decide between manual, semi-automatic, or fully automatic based on your workflow.

5.Space Constraints: Consider the machine's footprint in your workshop or factory.

6.Budget: Balance initial investment with long-term productivity gains.

7.Maintenance Requirements: Factor in ongoing maintenance costs and ease of service.

Carefully evaluating these aspects will help you select an edge banding machine that best suits your specific needs and constraints.

Edge banding machines have expanded the horizons of furniture design in several ways:

1.Material Variety: The ability to apply different edge banding materials allows for creative color and texture combinations.

2.Curved Edges: Advanced machines can apply edge banding to curved and shaped panels, enabling more dynamic designs.

3.Thickness Options: Machines can handle various edge banding thicknesses, from thin strips to thick solid wood edges.

4.Seamless Integration: High-quality edge banding can create the illusion of solid wood construction in engineered panels.

These capabilities give furniture designers greater freedom to explore innovative concepts while maintaining practicality and cost-effectiveness in production.

Proper maintenance is essential for keeping your edge banding machine in top condition:

1.Regular Cleaning: Remove dust and debris from all components, especially glue applicators and cutting tools.

2.Lubrication: Keep moving parts well-lubricated according to the manufacturer's recommendations.

3.Adhesive System Maintenance: Clean and maintain glue pots and applicators to prevent clogs and ensure consistent bonding.

4.Cutting Tool Sharpening: Regularly sharpen or replace trimming and cutting tools for clean, precise edges.

5.Calibration: Periodically check and adjust machine settings to maintain accuracy.

Following a comprehensive maintenance schedule will prolong the life of your edge banding machine and ensure consistent, high-quality results.

The edge banding machine industry is constantly innovating, with recent advancements including:

1.Increased Automation: More sophisticated control systems for reduced operator intervention.

2.Improved Precision: Enhanced sensors and controls for even tighter tolerances.

3.Energy Efficiency: New designs that reduce power consumption without sacrificing performance.

4.Smart Connectivity: Integration with production management systems for real-time monitoring and data analysis.

5.Versatility: Machines capable of handling a wider range of panel materials and edge banding types.

These technological improvements are making edge banding machines more efficient, versatile, and indispensable in modern furniture manufacturing.In conclusion, edge banding machines have become an integral part of the furniture industry, revolutionizing production processes and enabling higher quality, more diverse designs. As technology continues to advance, these machines will undoubtedly play an even more significant role in shaping the future of furniture manufacturing.Key takeaways:

-Edge banding machines are essential for creating professional, durable furniture edges.

-They come in various types to suit different production scales and needs.

-These machines significantly improve efficiency, quality, and design possibilities in furniture manufacturing.

-Proper selection and maintenance of edge banding machines are crucial for optimal performance.

-Ongoing technological advancements are making edge banding machines even more valuable to the furniture industry.

By understanding and leveraging the capabilities of edge banding machines, furniture manufacturers can stay competitive, innovative, and responsive to market demands in an ever-evolving industry.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat