Are you tired of looking at the unsightly edges of your plywood or melamine projects? Installing edge banding is the perfect solution to give your woodworking a polished, professional finish. In this comprehensive guide, we'll walk you through the process of applying edge banding, from selecting the right materials to achieving a flawless result. Whether you're a DIY enthusiast or a professional woodworker, this article will equip you with the knowledge and techniques to master edge banding installation. Let's dive in and transform your projects from ordinary to extraordinary!

Edge banding is a thin strip of material, typically made of wood veneer, PVC, or melamine, that is applied to the exposed edges of engineered wood products like plywood or particleboard. But why is it so crucial in woodworking?Edge banding serves several important purposes:

1.It conceals the layered structure of plywood or particleboard, giving a more finished appearance.

2.It protects the edges from moisture and damage, extending the life of your project.

3.It provides a seamless look that matches the surface of your material.

Without edge banding, your projects may look unfinished and be more susceptible to damage. By mastering this technique, you'll elevate the quality and durability of your woodworking creations.

When it comes to edge banding, you have several options to choose from. Each type has its own unique characteristics and applications:

1.Wood Veneer Edge Banding: Made from thin slices of real wood, this type offers a natural look and feel.

2.PVC Edge Banding: A durable and water-resistant option, perfect for high-moisture areas.

3.Melamine Edge Banding: Matches melamine-coated particleboard and is easy to apply.

4.ABS Edge Banding: Known for its impact resistance and color stability.

The choice of edge banding material depends on your project requirements, budget, and desired aesthetic. Consider factors such as the substrate material, environmental conditions, and the overall design of your piece when selecting the appropriate edge banding.

Accurate measurement and cutting are crucial for a professional-looking edge banding application. Here's how to get it right:

1.Measure the length of the edge you need to cover, adding an extra inch for trimming.

2.Use a sharp utility knife or specialized edge banding trimmer to cut the banding to size.

3.For curved edges, measure the circumference and add a little extra to ensure full coverage.

Remember, it's always better to cut the edge banding slightly longer than needed. You can easily trim excess material later, but you can't add length if you cut it too short.

Having the right tools can make the edge banding process much smoother. Here's a list of essential tools:

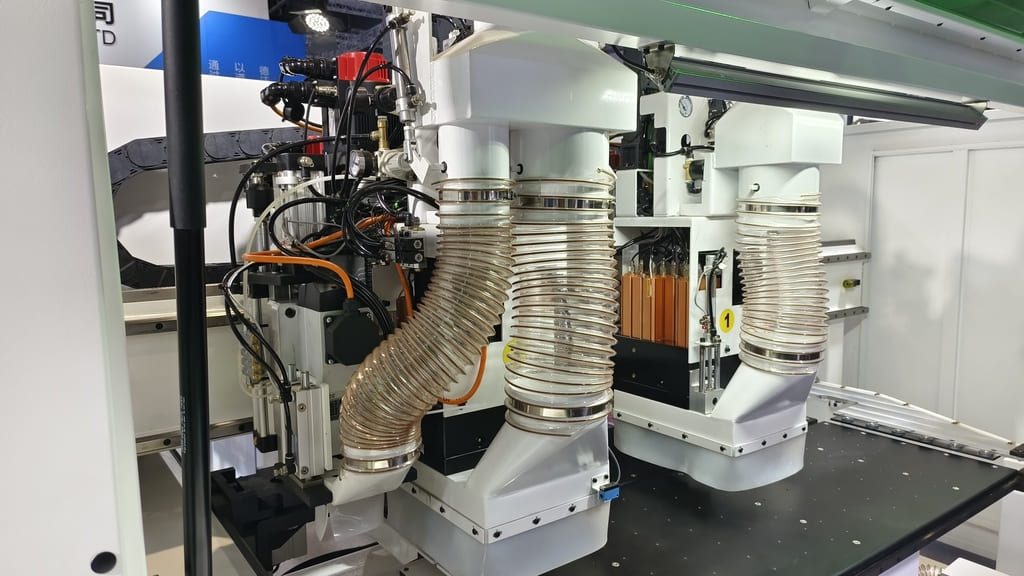

-Iron or edge banding machine

-Trimmer or sharp utility knife

-Sanding block or fine-grit sandpaper

-Clean, lint-free cloth

-Adhesive (if using non-pre-glued banding)

For those who frequently work with edge banding, investing in an edge bander machine can significantly speed up the process and improve consistency.

Proper surface preparation is key to achieving a strong bond and smooth finish. Follow these steps:

1.Ensure the edge is clean, dry, and free from dust or debris.

2.Sand the edge lightly to create a slightly rough surface for better adhesion.

3.Wipe the edge with a tack cloth to remove any remaining particles.

Taking the time to properly prepare the surface will pay off in the long run, resulting in a more durable and professional-looking edge banding application.

Iron-on edge banding is a popular choice for its ease of use. Here's a step-by-step guide:

1.Set your iron to the appropriate temperature (usually medium-high).

2.Position the edge banding, ensuring it slightly overhangs on all sides.

3.Starting at one end, slowly move the iron along the banding, applying even pressure.

4.Continue ironing until the entire length is adhered.

5.Allow the banding to cool before trimming.

Remember to keep the iron moving to prevent scorching or overheating the adhesive. For larger projects, you might consider using an edge banding machine for more consistent results.

After applying the edge banding, proper trimming and finishing are essential for a professional look:

1.Use an edge banding trimmer or sharp utility knife to remove excess material from the sides.

2.For the ends, use a flush-trim router bit or carefully trim with a knife.

3.Sand the edges lightly to smooth any rough spots.

4.Use an edge scraper to achieve a perfectly flush surface.

Take your time during this step to ensure a seamless transition between the edge banding and the surface of your material.

Even experienced woodworkers can make mistakes with edge banding. Here are some common pitfalls to watch out for:

-Applying too much heat, which can damage the banding or substrate

-Not allowing enough cooling time before trimming

-Rushing the trimming process, resulting in uneven edges

-Neglecting to sand or finish the edges properly

By being aware of these potential issues, you can take steps to avoid them and achieve better results in your edge banding projects.

Proper maintenance can extend the life of your edge banded projects:

-Clean regularly with a damp cloth and mild soap

-Avoid exposing edge banded surfaces to excessive moisture or heat

-Address any lifting or peeling edges promptly to prevent further damage

For minor repairs:

1.Gently lift the loose edge

2.Apply a small amount of contact cement

3.Press firmly and allow to dry

For more extensive damage, it may be necessary to remove and replace the affected section of edge banding.

As you become more comfortable with basic edge banding, you might want to explore some advanced techniques:

1.Wrapping curved edges

2.Creating inlays with contrasting edge banding

3.Using multiple layers of edge banding for a unique look

4.Applying edge banding to irregularly shaped pieces

These techniques can add a distinctive touch to your woodworking projects and showcase your skills as a craftsperson.

Edge banding is more than just a functional element; it can significantly enhance the aesthetics of your woodworking:

-Create a cohesive look by matching edge banding to the surface material

-Use contrasting edge banding for a bold, modern design

-Experiment with textured or patterned edge banding for added visual interest

-Combine different widths of edge banding for a layered effect

By thoughtfully incorporating edge banding into your design, you can elevate simple projects into stunning pieces of craftsmanship.In conclusion, mastering the art of edge banding installation can dramatically improve the quality and appearance of your woodworking projects. Here are the key takeaways to remember:

-Choose the right type of edge banding for your project

-Properly prepare the surface before application

-Use the correct tools and techniques for application and trimming

-Take your time and pay attention to detail for professional results

-Maintain your edge banded surfaces for longevity

-Explore advanced techniques to enhance your woodworking skills

With practice and patience, you'll soon be applying edge banding like a pro, transforming ordinary plywood and melamine into beautiful, finished pieces.

Contact: RicoCNC

Phone: 0086-13390848665

E-mail: cncsale@ricocnc.com

Whatsapp:0086-15264185266

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

We chat